Spice processing

Practical Action

Grading

Spices can be graded by size, density, colour, shape and flavour. Machines are available for

larger scale production units.

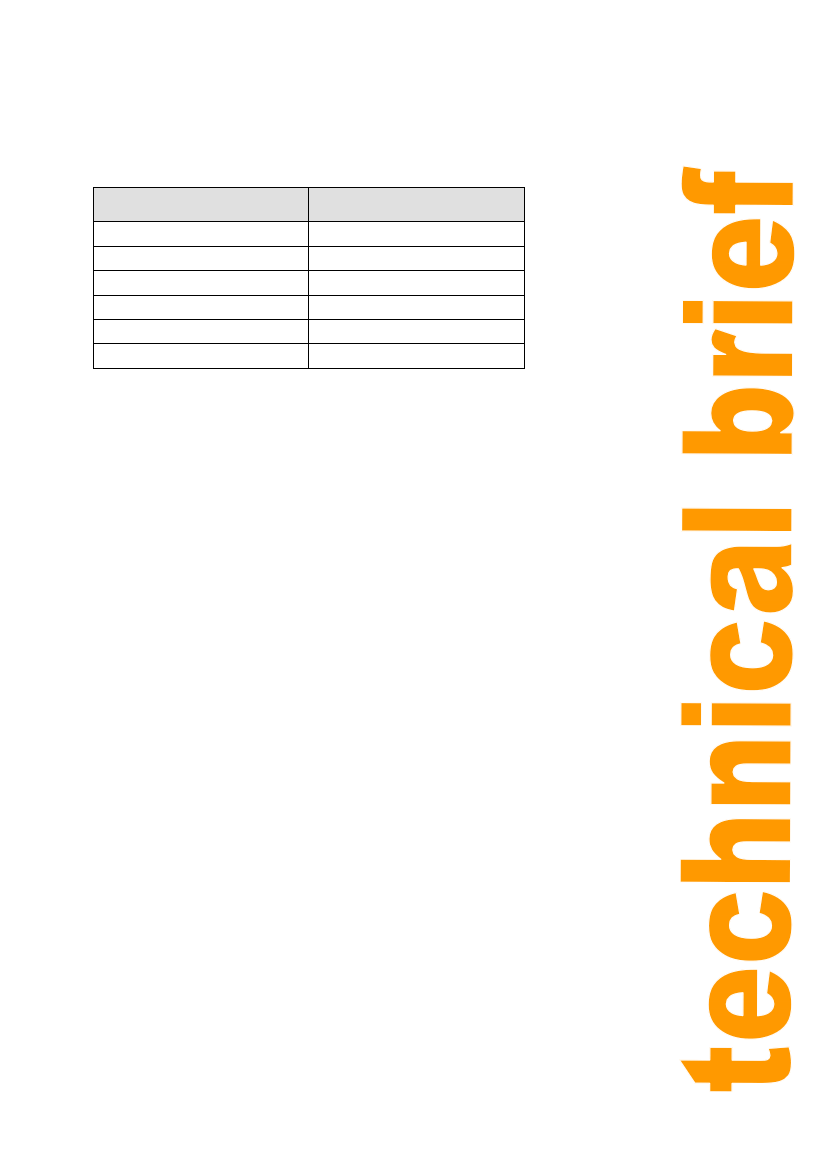

Spice

Mace

Nutmeg, cloves

Turmeric, coriander

Cinnamon

Pepper, pimento, chillies, ginger

Cardamom

Maximum final moisture content

(% wet basis)

6.0

8.0

9.0

11.0

12.0

13.0

Table 1: Spice moisture content

Grinding

Spices can either be sold whole or ground into powder. Grinding can add value to the product,

but it can also detract from the quality of the product. Many consumers are wary of ground

spices since they are frequently contaminated or adulterated. There is no easy way to determine

whether ground spices are pure or have been adulterated. In general, ground spices are made by

grinding inferior and broken spices. Also, ground spice has a much shorter shelf life than the

whole spice. Once it is ground, the flavour and aroma of spice soon deteriorate. It is better for

the small-scale processor to sell whole spices. This also removes the need for moisture proof

packaging materials and sealing machines.

For small-scale production (up to 100kg/day) manual grinders are adequate. Small Chinese or

Indian models designed for domestic spice grinding are suitable. A treadle or bicycle could be

attached to make the work easier.

For larger scale production a small, powered grinding mill is needed and models are available

that can grind 25kg/hour. A grinding mill needs to be placed in a separate and well ventilated

room because of the dust. Great care is needed to ensure uniform sized pieces/powders after

grinding and also to prevent heating of spices during grinding.

Packaging and storage

After drying, the material should be packed quickly into clean heavy gauge polypropylene sacks

to avoid any moisture pick up. The spices must be cool before they are packed into the sacks

and they must be stored out of direct sunlight to prevent condensation forming on the inside of

the sack. Workers should not directly handle the spices, but should use clean gloves and scoops.

Sacks should be labelled and dated.

The packaging requirements depend on: 1) the type of spice, 2) whether it is ground or intact

and 3) the humidity of storage. Most intact spices will store adequately in sacks/boxes if the

humidity of the air is not too high. Ground spices can also be stored without special packaging if

humidity is low but over long periods there is a loss of flavour and risk of contamination and

spoilage.

It is therefore better to store spices in a barrier film such as polypropylene (essential in areas of

high humidity) to provide an attractive package, retain spice quality and prevent contamination

and losses. If polypropylene is not available, cellulose film is adequate if it is heat sealable.

Polythene is a poor substitute and should only be used for short term storage as it allows the

flavour/aroma of the spices to escape.

3